We’re here to help (07) 5520 4422

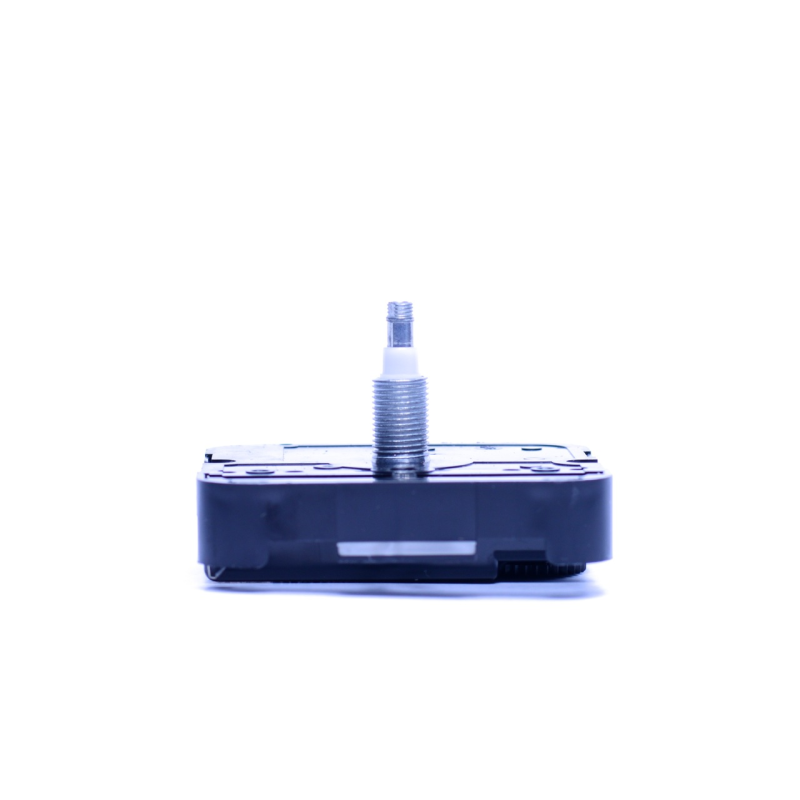

USA Made Mini High Torque Movement 10mm-16mm

Pricing Discounts

| QTY | PRICE (PER UNIT) |

| 5–9 | $22.50 |

| 10–19 | $20.00 |

| 20 + | $17.50 |

US made Takane Mini Quartz High Torque Clock Movements.

These movements will work all of the clock hands* listed on this website.

Available in 2 sizes -to suit up to 10mm & up to 16mm dial thicknesses.

* Hour & minute hand only. They are not bushed to work a second sweep.

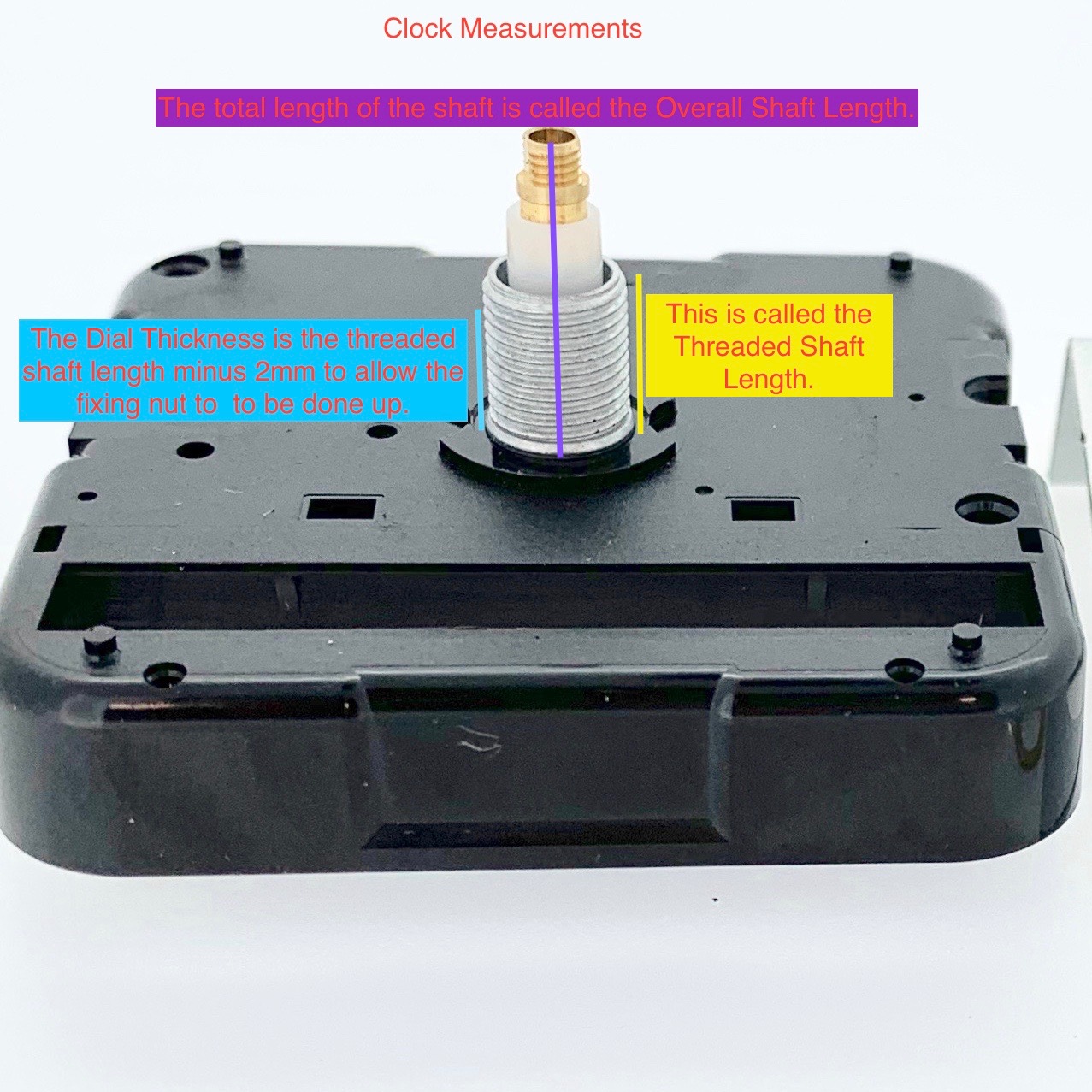

To choose the proper shaft length size carefully measure the thickness of the material that the clock shaft needs to go through. These clocks are sold by dial thickness and a variety of shaft lengths may be combined to obtain a quantity discount which is calculated at the checkout.

| Dial Thickness | Threaded Shaft | Overall Shaft | |

| HT10AA | 10mm | 12mm | 22mm |

| HT16AA | 16mm | 18mm | 29 mm |

If in doubt which size you will need it is better to purchase slightly larger rather than smaller.

Movement Dimensions 55 x 55 x 15 mm

Diameter of threaded shaft. 8 mm

Life expectancy 10 years

Accuracy within 2 minutes per year.

Battery size AA

These prices include the clock movement & necessary hardware.

Hands and Numbers need to be ordered separately.

Janines tip . Remember to check that there will be enough room between the clock dial and the clock lens when repairing or making a clock. You need 12mm to prevent the hands from touching the glass.

This movement will work all of the hands on this website up to and including hands 450mm long.

It is often best to purchase new hands when purchasing a new clock movement to ensure everything is going to fit perfectly and the hands are balanced accurately.

If you are repairing a clock and have a set of hands from the exisitng clock that you would like to use you will most likely be able to use them if minute hand will need to be the "I" shaft style which means that minute hands is held on by a small nut.

If you are repairing a clock movement it is still advisable to purchase new hands as well as giving the clock a nice fresh look it assures a good fit. ( It is easy to damage the clock shaft when attempting to fit wrongly bushed hands and this is not covered by warranty.)

- I have been tested at the shop before packing and have arrived ready to give you many years of accurate tick tocking.

- I want us to have a long and happy relationship so here are my rules.

- Ouch don’t use pliers to tighten the hex nut!!! Gently finger tighten only!!!!!! (I wouldn’t use pliers on you!)

- Using hands designed to work on a different brand / style of clock may damage me and will void the warranty.

- I am not designed for weight bearing. Ensure that the clock shaft is not responsible for bearing the weight of the clock.

- DOUBLE SIDED TAPE IS A GREAT WAY TO SECURE THE MOVEMENT TO THE BACK OF THE FACE OF THE CLOCK.

- If my hour hand seems too tight. Gently scrape the inside of the hole with a penknife blade to enlarge the hole. Don’t try and force me onto the hour shaft

- I hate fumes - make sure that I can breathe. Timber and thinner fumes get into the plastic workings and clog them up….

- For high Torque movements please don’t bend the hands- when they are on the clock. The large hands can damage the movement when they are bent whilst still on the clock. Remove the hands to do this and then put them back on the clock.

- If you treat me right I will be accurate to within 2 minutes per year and last for about 10 yrs.

© Let's Make Time Clock Company 2024. All rights reserved. Powered by SiteSuite